User:Denoyelle/Food Coating

Food coating new article content ...

'Coating is an industrial process which consists in applying a liquid or a powder onto the surface of a product of any possible shape in order to convey new properties. Coating designates an operation as much as the result of it : the application of a layer and the layer itself. Coating takes much different meanings depending on the industry concerned : steel, paper, chemical, plastic, pharmaceutical, food industries among others.

Definitions[edit]

The present article concerns coating applications in the food industry. There are many similarities between coating processes and numerous examples of technology transfer to and from the food industry.

Getting started

What coating is in the food industry: the application of a thin / thick layer of liquid and / or powder onto a product of a sizeable shape. The operation essentially relies on mecanichal energy and physical principles. It consists mostly in setting the product particles in movement and simutaneously applying the coating ingredient in a certain pattern in order to expose one to the other. It involves such phenomenons as attraction, friction, cristalyzation).

What coating is in other industries such as steel, plastic processing: the application of one or more generally thin layers of a standardized chemical liquid and / or powder, usually of high resistance to convey very specific functionnal properties. For example, protection against wear or corrosion, a barrier against ultraviolet, lesser friction... The English term is often used in foreign languages to describe such an operation.

What coating isn’t : the application of a liquid layer on very small particles. It is rather called encapsulation. It relies on an array of principles: entrapping a molecule inside a matrix, chemical bonding, polymerisation. Encapsulation aims at the protection and controlled release of active molecules when immersed in an environment. As a rule of thumb, particle size can discriminate between “encapsulation” (below 300 to 1000 µ) and “food coating” (above this limit). Mere mechanical movement is not adequate and sufficient to fulfill the proper coating of minute particles.

What coating isn’t either in the food industry: a science. It is based on experience. Food coating is not a “hard” science such as drying, cooling which can be described by equations and be predictable. Food coating is rather a “soft” knowledge derived from the accumulation of know-how. One reason is that product and ingredients considered have complex characteristics and interactions. They obeys to fuzzy logic, an expert systemif ever designed would count numerous branches in the decision tree. Consequently, coating is often a problem neglected in project planning until time and budget run short toward the end. Food coating is also not a subject taught as such in schools. But surely enough, food coating will benefit more and more of the knowledge gathered in the chemical industry re viscosity, surface tension.

The words to say it

The vocabulary used reflects the large diversity of applications: panning of dragees, , flavouring of snacks, enrobing of chocolate, glazing and sealing of sweets…

The words to say it abroad

- German : Uberziehung, Beschichtung

- French : enrobage

- Itlian : copertura, ricorpertura, rivestimento

- Spanish : recubrimiento

Theory[edit]

Examples of coated products

Hereafter are listed the major types of food coated products and processing details.

| Finished product | Base | Ingredient | Post treatment | Rate % | Objective |

|---|---|---|---|---|---|

| Coated seeds | Seeds | Binder, clay | Drying | 30-100% | calibration, protection |

| Ready-To-Eat Cereals | Expanded cereals | Sugar syrup | Drying | 20-50% | flavour and appearance enhancement |

| Petfoods | Extruded cereals | Fat, palatant | Cooling | 5-30% | Palatability, energy |

| Dragees | Nuts, chocolate, sweet | Sugar | Panning | 10-100% | Taste, flavour |

| Chocolate | Hazelnuts, almonds | Chocolate | Cooling | 30-50% | Taste, flavour |

| Prepared vegetable | Frozen vegetables | Water, fats, flavourings | Freezing | 15-100% | taste, convenience |

| Processed cheese | Grated/shredded cheese | Anticaking | None | 0,5-1,0% | Prevent agglomeration |

| Nuggets | Meat | Batter and crumb | Frying | 30-100% | palatability |

| Snacks | Expanded flour | oil and seasoning | None | 5 - 40% | palatibility |

| Crunchy nuts | Peanut | Flour, binder, seasoning | Frying, oven | 30-100% | palatability |

| Prepared foods | Prepared foods | Gelee | Cooling | 30-100% | aspect, palatabity |

| Tablets | Tablet core | film forming substances : hydrocolloid, resin | Drying | 1-10% | protection |

Pictures

-

Sugar-coated rice.

-

IQF Vegetables coated with cream.

-

Sugar-coated dragees.

-

Film-coated seeds.

Objectives of coating[edit]

Organoleptic Coating triggers :

- Sight : colour, (white dragee, brown chocolate), surface aspect ( glazed sweet, rough crispy nugget);

- Taste: sweet dragee, salted snack;

- Flavour ;

- Texture : crispy nugget.

Nutrition Coating brings :

- Vitamines, minerals ;

- Energy.

Functional Coating conveys properties : easy glide (oiled sweets), non sticky (chocolate dragee), anticaking (shredded cheese), oxydation-free (sultanas), consistent dosing (coated seeds) The most sought after and difficult to achieve is a barrier effect:against water migration between a layer of ice cream and a biscuit, against moisture lost of chewng gum. Money An ingredient may by cheaper than the product it coats and thus allows for a slight cost reduction.

The coating process[edit]

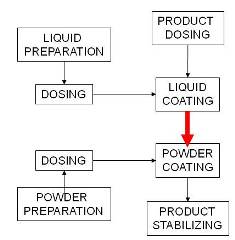

The process achieves the application of a liquid and/or a powder on the food product. The end product must be stable throuhgout its shelf life. Therefore a coating process is completed by a stabilizing process, either by freezing, cooling, heating, drying. Sequences of the coating process

- Spraying : especially when minute quantity of an ingredient has t be applied, it is advisable to disperse it first instead of just pouring it. It quickens the dispersion on the whole surface of the porduct and homogeneity.

- Adhesion: the ingredient has to adhere to the product, meaning that there must be a degree f affinity between the ingredient and the product.

- Coalescence : in case of a liquid, the mulitple droplets have to merge to form a uniform continuous layer. Characteristics of the ingredient in relation to the product, such as surface tension associated to a mechancial effect (friction) are critical.

- Stabilization : according to the nature of the ingredient and if the product allows it, the ingredient is stabilized by : elimination of the solvent (drying and evaporation of water, alcohol), cristalization (sugar cristalizes when water is evaporated, fat crystalizes when cooled), thermal treatment (proteins sets irreversibly when heated).

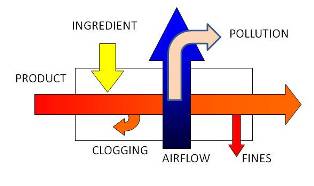

Coating as a system

.

A coating process can be broken into the following elements :

- Inputs : base product, additives and ingredients.

- Additional flows : air as a carrier ou for drying, energy in mechanical (agitation, transfer, friction) or thermal form (convection, conduction or radiation heating).

- Outputs : end product, excess ingredients.

Collaterals occur along the process:

- Breakeage of product.

- Generation of fines.

- Agglomeration of products.

- Clogging of system surfaces with product or ingredient

- Airborne pollution, COV

These effects need to be avoided unless the process may be hindered within a limited time range. The parameters of the system Parameters affecting the system are listed by origin:

| Base product. | End product. | Production |

|---|---|---|

| Shape, size, distribution, bulk density, nature, surface aspect, resistance , composition, flow behaviour, fines, hygroscopicity, temperature. | Capacity, end aspect, weight gain, storage behaviour, resistance. | Recipe changes, duration, cleaning. |

This first set of criteria governs the choice of the coating ingredient. The coating consists either in a single ingredient or a mix. This mix has different physical forms : solution, emulsion, suspension, powder… It has its own characteristics. In addition, a fluid may be required such as spraying, cooling, heating or drying air..

| Additive. | Fluid. |

|---|---|

| Water or fat base, composition, concentration, viscosity, tempeature, melting point, surface tension, setting behaviour. | Nature, temperature, relative humidity. |

The combination of the above characteristics drives the choice of the process principle. It has then to be precisely described.

| Process. | Machine. |

|---|---|

| Continuous, batch, residence time, ingredient temperature, fluid temperature, system temperature, flow volumes , tolerances t variations, number of functions to fulfill (feeding, dosing, recycling, drying...) | Form, internal surface, internal volume, size, mechanical movement, speed, temperature. |

The selection of the proper process and its control rely on the gathering of precise and reliable information.

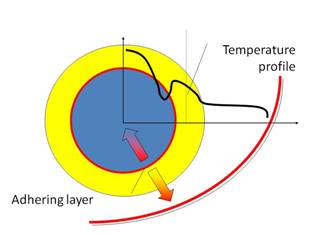

The influence of some phenomenon and their parameters is critical : cristalyzation, water removal (drying), glass transition, viscosity, surface tension... Temperature. Among the parameters, temperature has a choice place. It influences viscosity, surfae tension, drying or cristalyzation behaviour. Ultimately, it influences the coating rate (thickness, weight gain), coating resistance. It therefore influeneces the degree of clogging of product, ingredient in the system. For example, fat will tend to set preferably on a cool product if the system wall is kept at a higher temperature.

Pratice.[edit]

Coating ingredients.[edit]

Hereafter a non limited list of coating ingredients or mixes.

| Ingredient | Form | Usual coating rate. | Characteristics related to coating. | Coating aim. | Examples |

|---|---|---|---|---|---|

| Water. | Pure liquid. | 1-3% | Wetting, adhesion, weight gain. | Dust prevention. | |

| Water. Eau | Saturated steam. | 1-3% | Wetting, adhesion. | Gluing of sugar on candies. | |

| Alcohol | Solution 70% | 0,1% | ALcohol rate. | Antimicrobial, preservative, texture enhancement. | Preservation of packed pastries. |

| Resin : shellac. | Alcoholic solution 30%. | 1% | Film forming. | Surface aspect, gliding, moisture barrier. | Shining of chocolate dragees. |

| Wax : beewax, carnauba, candelilla wax. | Solid form, melted, micronized suspension in oil. | 1% | Melting point. | Surface aspect, barrier. | Shining of sugar dragees. |

| Sugars : saccharose, glucose, honey, polyols... | Solution 70-90% | 1-100% | Crystalization form, concentration, temperture. | Palaability, surface aspect (glazed or frosty). | Sugar-coated ready-to-eat cereals. |

| Polymers : acetate, povidone, cellulose. | Dispersion 10% | 1% | Concentration, film forming ability, glass transition point, barrier. | Mechanical or chemical protection. Carrier of additives. | Seed coated with herbicide or pesticide. Pelliculage |

| Natural [[hydrocolloids : Gum Arabic, xanthan, guar gelatine… | Solution 20-40% | 3% | Film forming, barrier. | Mechanical or chemical protection. Carrier of additives. | Precoating of dragee with Gum Arabic and sugar prior to dragee pan coating. |

| Starches : native, modified starches. | Colloidal solution 20-40% | 3% | Characteristics depending on physical and chemical modifications. Substitues for more expensive ingredients (Gum Arabic, gelatine, titane dioxyde…). | Mechancical or physical protection. Protection mécanique, physique, chimique | Coating of fries before frying to reduce oil pick up. |

| Flours. | Powder or thick suspensions 20-40%. | 10-20% | Film forming, charge, viscosity, baking expansion. | Thickness, crispiness. | Coating of nuggets with batter prior to breading. |

| Mineral or organic powders : talc, cellulose, potato flour, cellulose, starch… | Pure powder. | 1% | Moisture or fat absorption. | Anticaking, drying. | Coating of shredded cheese to prevent agglomeration. |

| Oils and fats. | Pure | 1 - 40% | Melting point, viscosity. | Anticaking, adhesion, barrier against moisture migration. | Oiling of dry raisins or inclusions in ice cream. |

| Seasonings, flavours, flavour enhancers, salt. | Powder, diluted or concetrated solutions. | 1-3% | Concentration | Palatability. | Flavouring of expanded snacks. Salting of pistachos. |

Coating techniques.[edit]

For the sake of classification, 2 categories can be split easily : necessarily batch or continuous processes. Then the categories can be refined according to the way the product is set in motion and the ingredient applied. Then, techniques allow only for coating or for combined coating and setting.

| Name. | Principle | Example | Alternative | Batch/Continuous |

|---|---|---|---|---|

| Fluidized bed | Lifting of the product by air, simultaneous spraying of a solution, instant drying. | Film-coated seeds. | Vertical batch fluid bed, horizontal continuous fluid bed | Batch/Continuous |

| Coextrusion. Co-extrusion | Forming of an outside casing around a inner content. | Forming machine for sausages with forming of a vegetable casing. Further setting by coagulation and drying. | High-temperature short-time cooking-extrusion of snacks with continuous filling of a flavoured paste. | Continuous . |

| Paddle mixer. | Mixing by agitation in a closed volume. | Seed coating. | Helicoidal, scraping paddles. | Batch |

| Vat mixer. | IQF coating (and freezing) tumbler. baratte pour enrobage par surgélation | Vaccuum mixing. | Batch. | |

| Conveyor. Convoyeur | Application of the ingredient on the product spread accross a conveyor. | Topical coating of pastries. | Spraying, screen, dipping coating. | Continuous. |

| Drum. | Application of the ingredient while the product is tumbled in drum. | Simultaneous coating and drying of cereals with sugar. | Continuous. | |

| Screw. | Application of the ingredient while the product is transferred and mixed in a trough fitted with screw(s)). | Petfood. | Twin-screw systems for a better mixing. | Continuous.

- |

Criteria for the selection of a technique.

- Base product characteristics : shape, size, bulk density.Size is the first criterium.

- Mechancial resistance of the base product.

- Final thickness of the coating layer.

- Complete/partial, top/side/bottom coating.

- Number of sequences to repeat.

- Processing time for each sequence.

- Setting mode : drying, cooling, freezing…

- Capacity.

- Preferred batch or continuous system.

Comparison batch vs. Continuous.

The demand for higher yields makes production managers want to shift fom manual batch to continuous automated systems. One has to consider the pros and contras prior to go for acostly and risky decision.

| Batch. | Continuous. | |

|---|---|---|

| Advantages | Flexible, easy to monitor and control, quick response, less time dependent, easy recipe change, full traceability, tool for R&D. | Efficient, justified if upstream and downstream processes are continuous. |

| Drawbacks. | Limited capacity. Manpower. | Expansive. REquires careful controls and feedbacks, consistent feeding and peripherals. |

Peripherals.[edit]

Given the number of operations and steps, a coating process can quickly become complex. The process core machine requires peripheral s to service it. A few standard ones are listed for information.

- Storage.

- Ingredient preparation.

- Product feeding and metering.

- Ingredient dosing.

- Filtration or sieving.

- Application system.

- Recycling.

Measures[edit]

Test results can be immediately evaluated (visual aspect) but are preferably assessed by careful measures : to allow monitoring, to agree on commissioning, to certify conformity with customer requirements. Typica measures / :

- Optical : colour, microscopy (homogenety, thicness), image analysis.

- Weighing : weigning before and after treatment, weighing between batches or particles.

- Specific measurements according to target : compaction, barrier property.

About coating.[edit]

Project management.[edit]

Information need to be gathered carefylly along the above mentionned lines : base product, end product, ingredient, production constraints… Functions to fulfilly need to be clearly defined (Functional analysis, value analysis). A preferred technique alone should not command decisions. A process is as much the result of the prduct target specifications as the production and technical environment conditions. Project steps. The development of a product dwells on limited time and money resources. A progressive approach spares both.

- Office : preliminary analysis based on samples in order to define the technique.

- Laboratory : test on 100 g to 1 kg to demonstrate the physical feasibility and gatehr the parameters. Can the product only be coated with this ingredient?

- Pilot. Test on 10 to 100 kg to demonstrte that what has been done manually can be mechanized and to prepare scale-up.

- Industrial test : test on 100 kg to tons to assess the durability of the process in industrial conditions.

Partners. A coating process involves several partners :

- Final marketer of the product.

- Product manufacturers, sub-contractor, actual user of theprocess.

- Ingredient producers.,

- Machine manufacturers.

- Research centers.

Some advices. Coating is an easy operation in itself. Make the process last is the challenge. Coating is nothing without the setting phase to which it is intrisecally tied. The devil hides into the details. Minor factors can have huge detrimental affects on the viability of the product and process. Coating is more practice (trial and error) than science (equations). Consequence : scale up requires repeated evaluations as the volumes tested grow. The choice of a coating technique is very dependent upon external conditions rather than the process itself. Coating is a threesome play : product, ingredient, machine. Common sense tells that the ingredient and machine should adapt to the product arget, but a slight change in an ingredient can make a big difference in how easy the machine works. Managing the peripherals is often the most difficult task in running the process. Being at the end of the process line, the coating process receives little attention, time until the end of the project where suddenly panic is rised over deadlines and budget limits.