Talk:Centrifugal pump

| This article is rated Start-class on Wikipedia's content assessment scale. It is of interest to the following WikiProjects: | |||||||||||||||||||||

| |||||||||||||||||||||

Disambiguation?[edit]

I don't believe that this needs to be a disambiguation page. For a start, someone has already started explaining what a Centrifual Pump is. I think there is more than enough scope for an article on centrifugal pumps here. I'll work on it, and invite others to help. Removing disambiguation now, and keeping existing links as "See Also". -Bernard S. Jansen 04:02, 17 November 2006

yea dats true

Over-Generalization/Non-specific[edit]

The statement "Centrifugal pumps are used for large discharge through smaller heads" is an over-generalization - what consists of a smaller head? I design systems at power generation facilities that use centrifugal pumps to pump slurry up over 150 feet of head through 56"+ lines at over 1,000 GPM! The applicability of centrifugal pumps are a factor of numerous considerations - not just the amount of head. Nick (talk) 20:53, 16 May 2008 (UTC)

what happens if we run centrifugal pumps in reverse direction kindly suggest. email d27737@gmail.com —Preceding unsigned comment added by 117.198.104.57 (talk) 16:02, 8 January 2009 (UTC)

I think they still will work in reverse direction, but will be extremely inefficient due to shock-loss. 74.60.57.253 (talk) 07:43, 1 August 2009 (UTC)

I agree with the previous post, the pump would be operating at a lower head/flowrate than one driven in the correct direction. In relation to the statement "Centrifugal pumps are used for large discharge....". This could be improved by a comparison, for example higher flow, lower head than positive displacement pumps. It is not clear whether the term centrifugal is inclusive of axial flow pumps which operate at much higher flow rates and lower heads than radial flow centrifugal.--GILDog (talk) 11:31, 2 August 2009 (UTC)

Unless the pump has been designed to operate as a hydraulic turbine, running it backwards is not a good idea. Many centrifugal pumps are direct connected to the driver, which you would be trying to drive backward. All centrifugal pumps I have seen installed in process plants have had a check valve on the discharge to prevent an accidental reverse flow for this reason. Moreover, other hazards could be created if a higher pressure fluid backflows through the pump into the lower pressure equipment.ChemE50 (talk) 18:29, 8 September 2009 (UTC)

Radial/Axial/Mixed Flow[edit]

What about Radial flow and Mixed flow pumps. There is come confusion as to what a centrifugal pump is. This article only deals with the Radial flow type of centrifugal pumps. Most literature I have seen also defines axial and mixed flow pumps as centrifugal pumps. --GILDog (talk) 13:10, 17 May 2009 (UTC)

Centrifugal Pump Curve Needed[edit]

A generic centrifugal pump curve would be very useful in explaining the design and operation of this type of pump. I have some curves that plot head vs. capacity with parameters of impeller diameter and/or pump speed. Unfortunately, they all have manufacturers' logos, so I believe they are unacceptable per Wikipedia rules. Can another reader supply a suitable curve?ChemE50 (talk) 18:11, 8 September 2009 (UTC)

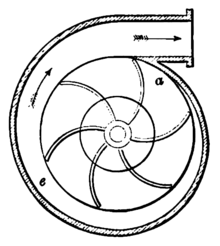

Incorrect impeller vane direction in cutaway image[edit]

This article references an image showing a cutaway of a single stage centrifugal pump: File:CetriFugal_Pump.jpg

Several other Wikipedia language pages use this image.

It is a great image, except that the impeller vanes are the wrong direction with respect to the outlet. I made a corrected albeit imperfect version using Paint.Net and uploaded it here: File:Centrifugal_Pump-mod.jpg

You can see other images showing the correct impeller vane direction here: File:Centrifugal_Pump.png and here http://www.britannica.com/EBchecked/topic-art/632655/7035/Volute-centrifugal-pump

The other way to know which way the impeller vanes should be orientated with respect to the outlet is to recognize that the impeller 'flings' the liquid away to the outlet. It does not 'cup' the liquid. Kaze0010 (talk) 22:46, 23 June 2010 (UTC)

- i can assure everyone the the direction the rotor vanes point in the cut-away is correct. anyone who says otherwise does not understand and should contact me immediately. looking into the inlet of the pump impeller and looking downstream the rotation of the rotor is correctly counter clock wise. — Preceding unsigned comment added by Mkoronowski (talk • contribs) 06:39, 21 April 2011 (UTC)

- Pump impeller blades can be curved either way. The image should not have been changed and I will attempt to change it back to the original one supplied. All images should not demonstrate their impellers as reverse curved when this usage would typically use a forward curved bladed impeller. The originl image was more correct. Here is some docs from a major manufacturer on this. See section 4.3. http://dk.grundfos.com/content/dam/Global%20Site/Industries%20%26%20solutions/Industry/pdf/The_Centrifugal_Pump.pdf — Preceding unsigned comment added by 99.251.125.65 (talk) 03:12, 24 June 2012 (UTC)

- i can assure everyone the the direction the rotor vanes point in the cut-away is correct. anyone who says otherwise does not understand and should contact me immediately. looking into the inlet of the pump impeller and looking downstream the rotation of the rotor is correctly counter clock wise. — Preceding unsigned comment added by Mkoronowski (talk • contribs) 06:39, 21 April 2011 (UTC)

Incorect link in problems[edit]

In Problems of centrifugal pumps I think the surge link going through to Jerk (physics) is incorect - its more a problem with water hammer or having a slug of water run backwards and stall the pump or even run it against its prime mover - having said that its a long time since I worked at BHR Group —Preceding unsigned comment added by Mjwalshe (talk • contribs) 13:11, 7 July 2010 (UTC)

Copyright problem[edit]

This article has been reverted by a bot to this version as part of a large-scale clean-up project of multiple article copyright infringement. (See the investigation subpage) This has been done to remove User:Accotink2's contributions as they have a history of extensive copyright violation and so it is assumed that all of their major contributions are copyright violations. Earlier text must not be restored, unless it can be verified to be free of infringement. For legal reasons, Wikipedia cannot accept copyrighted text or images borrowed from other web sites or printed material; such additions must be deleted. Contributors may use sources as a source of information, but not as a source of sentences or phrases. Accordingly, the material may be rewritten, but only if it does not infringe on the copyright of the original or plagiarize from that source. Please see our guideline on non-free text for how to properly implement limited quotations of copyrighted text. Wikipedia takes copyright violations very seriously. VWBot (talk) 06:00, 10 December 2010 (UTC)

Copyright problem[edit]

This article has been reverted by a bot to this version as part of a large-scale clean-up project of multiple article copyright infringement. (See the investigation subpage) This has been done to remove User:Accotink2's contributions as they have a history of extensive copyright violation and so it is assumed that all of their major contributions are copyright violations. Earlier text must not be restored, unless it can be verified to be free of infringement. For legal reasons, Wikipedia cannot accept copyrighted text or images borrowed from other web sites or printed material; such additions must be deleted. Contributors may use sources as a source of information, but not as a source of sentences or phrases. Accordingly, the material may be rewritten, but only if it does not infringe on the copyright of the original or plagiarize from that source. Please see our guideline on non-free text for how to properly implement limited quotations of copyrighted text. Wikipedia takes copyright violations very seriously. VWBot (talk) 13:02, 10 December 2010 (UTC)

Dick - what are you doing?[edit]

This is a page about a type of pump, nobody here wants to be drawn into a non-existent controversy about the meaning of 'centrifugal force'. Martin Hogbin (talk) 23:08, 13 February 2011 (UTC)

- Well, the "how it works" section was vacuous, and it seemed like writing from sources would make sense. The sources, as you know, are largely mixed up about how to do this, so I thought it best to point that out, too. Modern sources haven't gotten much better; have you been able to find one that describes sensibly how these things work? They mostly mention centrifugal force, without explaining what they mean by it. What would you suggest? Dicklyon (talk) 01:08, 14 February 2011 (UTC)

- I am sure that there must be a good modern description of how a cp works somewhere. Martin Hogbin (talk) 09:09, 14 February 2011 (UTC)

- In general, I resist the inclusion of purported controversies and such into WP – unless there's a reliable source for the controversy. Here we have many such. This field is very screwed up, and physicists and engineers know that, so they complain about it. One can't really understand the literature without understanding the objections to it. Dicklyon (talk) 02:44, 14 February 2011 (UTC)

- There is no controversy any more than there is a controversy over the spelling of the word 'centrifugal'. Look at these refs, [1], [2],. There are plenty more. Do we now suppose that there is a school of thought that the word should be spelled 'centrifugle' and that we should give equal weight to that POV? Martin Hogbin (talk) 09:27, 14 February 2011 (UTC)

The second figure, cutaway view of a centrifugal pump[edit]

The direction of the impeller vanes are correct! Looking downstream into the impeller the direction of rotation is correctly counterclockwise. If you have any questions please contact me, Mkoronowski (talk) 06:44, 21 April 2011 (UTC)

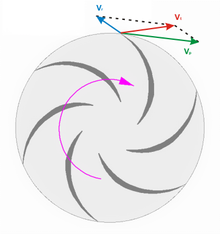

Next picture, a centrifugal pump uses a spinning impeller which normally has backward swept blades…[edit]

The back sweep of these blades is consistent with the clockwise rotation. However, this figure has to very severe mistakes. The velocity diagram shown with green red and blue vectors are obviously intended to be absolute velocity vectors and not relative velocity vectors. The reason I say this is that the length of the green vector represents the relative tangential slip velocity. It is too long by any stretch of the imagination. Further the relative frame of reference vectors are only used by fluid dynamics designers to shape the pump impeller blade.

The second error is to refer to the blades back sweep as directly pushing the water outward. This is all part of some layman's mumbo-jumbo. This figure should be corrected or removed.

Mkoronowski (talk) 06:53, 21 April 2011 (UTC)

How it works[edit]

I have a difficult time believing that any of the first six references used in this article Any academic standing at all. Any statements made in this article (and I see quite a few) that are based in part or in total on these references should be removed. I also have a hard time believing that the 2005 edition of the textbook of fluid mechanics could possibly can have contributed to how it works. The fundamental principles involved in the operation of the centrifugal pump impeller have been clearly outlined by any number of valid academic textbooks. The principals include: continuity the conservation of mass conservation of momentum based on one of newtons laws conservation of energy based upon Euler's pump and turbine equation and finally the equation of state which for water is constant density. While this is not my field of expertise, turbomachinery is and a centrifugal pump is turbomachinery. I am well prepared to correct this article if necessary. Mkoronowski (talk) 07:01, 21 April 2011 (UTC)

- That sounds an excellent idea. Martin Hogbin (talk) 10:22, 21 April 2011 (UTC)

- I would like to have your help. I am going to try an experiment. I am going to copy centrifugal compressors, strip it of most compressor specific material, leave the pictures as place holder and then paste it into a new discussion page...??? what do you think. best regards, martin koronowski, Mkoronowski (talk) 19:05, 21 April 2011 (UTC)

- I have to say that is not quite what I was expecting. I was hoping for a clear explanation of how a centrifugal pump works. Martin Hogbin (talk) 21:24, 21 April 2011 (UTC)

- Ok, i understand. can you give me a correct or incorrect example of what you mean. All of the simple explanations I have seen or heard tend to have serious scientific errors in them.

- I have to say that is not quite what I was expecting. I was hoping for a clear explanation of how a centrifugal pump works. Martin Hogbin (talk) 21:24, 21 April 2011 (UTC)

- I would like to have your help. I am going to try an experiment. I am going to copy centrifugal compressors, strip it of most compressor specific material, leave the pictures as place holder and then paste it into a new discussion page...??? what do you think. best regards, martin koronowski, Mkoronowski (talk) 19:05, 21 April 2011 (UTC)

- The best that I can do at this time is really weak. So here goes. A pump is a dynamic turbomachinery with the pump impeller adding kinetic energy to the fluid. It is through fundamental physics and alternating the frame of reference from stationary to rotating and back to stationary that allows a centrifugal pump to maintain a positive head. In contrast to is critical compressor that uses a diffuser to convert kinetic energy into potential energy (pressure energy) many pumps depend upon diffusion within the discharge of the centrifugal pumps volute. If we work at this together and maybe it will up with something that makes sense to some people. The difficulty arises in the curious and eager to learn that do not have the scientific or physics background to understand that this really is "rocket science". I see no reason why we can't put little effort into trying to explain this in a simple fashion that is correct and rigorous. I am neither a teacher or the sharpest pencil in the box so I really will need your help and will be very thankful for your patience. — Preceding unsigned comment added by Mkoronowski (talk • contribs) 22:36, 21 April 2011 (UTC)

- ooops my speech recognition is causing me some problems. I hope you can read through the above errors. Martin koronowski — Preceding unsigned comment added by Mkoronowski (talk • contribs) 22:38, 21 April 2011 (UTC)

- The best that I can do at this time is really weak. So here goes. A pump is a dynamic turbomachinery with the pump impeller adding kinetic energy to the fluid. It is through fundamental physics and alternating the frame of reference from stationary to rotating and back to stationary that allows a centrifugal pump to maintain a positive head. In contrast to is critical compressor that uses a diffuser to convert kinetic energy into potential energy (pressure energy) many pumps depend upon diffusion within the discharge of the centrifugal pumps volute. If we work at this together and maybe it will up with something that makes sense to some people. The difficulty arises in the curious and eager to learn that do not have the scientific or physics background to understand that this really is "rocket science". I see no reason why we can't put little effort into trying to explain this in a simple fashion that is correct and rigorous. I am neither a teacher or the sharpest pencil in the box so I really will need your help and will be very thankful for your patience. — Preceding unsigned comment added by Mkoronowski (talk • contribs) 22:36, 21 April 2011 (UTC)

test signature Mkoronowski (talk) 22:51, 21 April 2011 (UTC)

Please take the new draft to a subpage, and we'll talk about it here. You can start Talk:Centrifugal pump/new draft or something like that. And it would be better to stick to more conventional language and treatment, in which centrifugal pumps are usually pumping water or some such fluid, as opposed to the squirrel-cage fans, turbochargers, and jet engine compressors that you've loaded up the draft with. And the sources don't need to be academic, but some of that wouldn't hurt; especially if you can link online sources so people can follow up there when desired. The bibliography is useless; take it out and just use inline citations. Dicklyon (talk) 22:59, 21 April 2011 (UTC)

- If you transfer your draft to the page Dick suggests we can talk about it there. To start the page just click Dick's link and start editing. You can cut and paste what you have done. Martin Hogbin (talk) 23:34, 21 April 2011 (UTC)

- thankyou. what is a sub page?

- most of the blah blah is a place holder/ reminant from centrifugal compressor. it is intended to be rewritten for pumps.

- if you look at fluid dynamics, aerodynamics etc., the article is based upon academic sources. when you use buster's handbook on pumps you end up with arguments over centrifugal forces existing or not. pumps are rocket science and should be treated that way. nothing is gained by reading old wives tales. it really is comparable to rolling back history and using the church's explanation why planets orbit funny because earth is the center of the solar system. i'm fine with history but can't swallow warping what we know as fact because buster doesn't have the right academic background to understand what he was taught. i think referencing academic wiki articles, nasa & nist web sites falls within academic sources. i am a little upset with pump users and pump application engineers that write some of this stuff and act like an expert beyond their field.

- i will try the inline references. thanks , Mkoronowski (talk) 23:57, 21 April 2011 (UTC)

- That redlink I gave, with the slash in it, makes a subpage of this page. It's just another page, but has a slash in its name to indicate that it's subsidiary to this page. Copy your content, click the redlink, and paste it in and save, and it will become a blue link (a non-empty page). Dicklyon (talk) 00:45, 22 April 2011 (UTC)

Link to working copy, editting is in progress: Talk:Centrifugal pump/new draft

I've cleaned up here and put the previous draft at that subpage. Feel free to hack there. Dicklyon (talk) 04:06, 22 April 2011 (UTC)

- wow, thanks Mkoronowski (talk) 04:13, 22 April 2011 (UTC)

- The how it works section refers to figures and equations that are not in the article. Is this a cut and paste job from a textbook or were these just removed at some previous point in time? (Or is this a cut and paste job from a textbook where the images but not the text was removed)134.134.139.72 (talk) 20:01, 2 January 2019 (UTC) M. Michalski

Rotation direction and vane sweep direction, and figure arguments[edit]

Several sections above (#Incorrect impeller vane direction in cutaway image, #The second figure, cutaway view of a centrifugal pump, #Next picture, a centrifugal pump uses a spinning impeller which normally has backward swept blades…) complain of errors in figures, without showing which ones they are referring to. And a correct figure was recently reverted to an incorrect one, I think. So let's get explicit. Here are some figures. Which ones do people think are right or wrong? I've numbered them for reference here. Dicklyon (talk) 21:17, 25 June 2012 (UTC)

I'll start: 1–4 are correct; 5 has vanes backwards for the way the volute is shaped. Dicklyon (talk) 22:27, 25 June 2012 (UTC)

- You editwarred as this figure was reverted back to the original figure uploaded and posted. A discussion was in progress regarding this issue. The reason it was replaced with the original concept was to demonstrate that not all centifugal pumps have forward facing vanes and therefore not all figure here should be shown with forward facing vanes, for the sake of public education. This variabilty of angles can be found in most manufacturers bulletins. The backward facing vanes are not commonly found as percentage of total designs but it has its uses for more head in certain applications. OTOH the figure replaced was a very poor example due to the extreme lean back of the vanes. This doesn't happen in reality from what I have seen. See my link to a manufacturer bulletin in the section above regarding this same issue. So figure 5 could be correct but a very poor representation of forward leaning vanes. (overexagerated). There is some discharge chute angles to be considered to support various vane angles but this is out of my realm. See centrifugal fans where this is really common. 99.251.125.65 (talk) 20:27, 28 June 2012 (UTC)

- You seem to be agreeing with points I didn't attempt to make. Let me restate this as there is some confusion between your description and the usual industry terminolgy regarding vane angles. I will use the usual terminology manufacturers appear to. IOW I really screwed up in my explanation above. I hope this makes my point clearer.

- The reason I replaced the illustration with the original concept (picture) was to demonstrate that not all centifugal pumps have backward facing vanes and therefore not all figures here should be shown with backward facing vanes, for the sake of public education. This variabilty of angles can be found in most manufacturers bulletins. Forward leaning vanes are not commonly found (as percentage of total designs) but they have uses for more head in certain applications. OTOH the figure replaced by me (like fig 5) was a very poor example due to the extreme lean forward of the vanes. This doesn't happen, in reality, from what I have seen. See my link to a manufacturer bulletin in the section above regarding this same issue. So figure 5 could be correct but still a very poor representation of forward leaning vanes. (overexagerated). There is some discharge chute angles to be considered to support various vane angles but this is out of my realm. See centrifugal fans where this is really common. — Preceding unsigned comment added by 99.251.125.65 (talk) 13:02, 30 June 2012 (UTC)

- How it works has been written by a non expert. On a relative basis, I am an expert. I have designed pumps. The fundamental physics used in centrifugal gas compressors apply directly to centrifugal pumps. bringing up the issue of cavitation in response to this statement is proof that i am correct about a non expert. avoidance of cavitation in pumps changes many details, but it does not change the fundamental similarities. Next, Figure 2 shown here illustrates a highly back swept impeller. the Vt vector represents the total relative velocity (aka the total velocity in the rotating frame of reference). the Vr vector illustrates the radial velocity for both the relative and absolute frames of reference. the Vp vector represents the tangential relative velocity (again the relative frame of reference). the velocity vectors in the relative frame of reference are of interest to pump designers. the velocity vectors in the absolute frame of reference have a direct relation ship with power and capacity. this figure 2 has little in common with the existing text and helps confuse any logic. Finally, most pumps have backward swept vanes. The few that have forward swept vanes are either a specialty or not a kinematic turbo-machine. splitting hairs on forward sweep and backward sweep is a total waste of anything more than a paragraph and associated graphic. I have tried to contribute to this topic before and have tried to delete both incorrect figures and incorrect paragraphs. Unfortunately, I am a minor contributor to wiki and a very unskilled editor. It appears that key corrections have reverted to nonsense. Let me ask this, how many years of turbo-machinery design experience does anyone have? I am not an expert in pump applications, cavitation, vibration nor mechanical design (each of which is more important in high pressure/high power pump operation than hydrodynamic design.) — Preceding unsigned comment added by Mkoronowski (talk • contribs) 19:31, 10 July 2012 (UTC)

- How it works has been written by a non expert. On a relative basis, I am an expert. I have designed pumps. The fundamental physics used in centrifugal gas compressors apply directly to centrifugal pumps. bringing up the issue of cavitation in response to this statement is proof that i am correct about a non expert. avoidance of cavitation in pumps changes many details, but it does not change the fundamental similarities. Next, Figure 2 shown here illustrates a highly back swept impeller. the Vt vector represents the total relative velocity (aka the total velocity in the rotating frame of reference). the Vr vector illustrates the radial velocity for both the relative and absolute frames of reference. the Vp vector represents the tangential relative velocity (again the relative frame of reference). the velocity vectors in the relative frame of reference are of interest to pump designers. the velocity vectors in the absolute frame of reference have a direct relation ship with power and capacity. this figure 2 has little in common with the existing text and helps confuse any logic. Finally, most pumps have backward swept vanes. The few that have forward swept vanes are either a specialty or not a kinematic turbo-machine. splitting hairs on forward sweep and backward sweep is a total waste of anything more than a paragraph and associated graphic. I have tried to contribute to this topic before and have tried to delete both incorrect figures and incorrect paragraphs. Unfortunately, I am a minor contributor to wiki and a very unskilled editor. It appears that key corrections have reverted to nonsense. Let me ask this, how many years of turbo-machinery design experience does anyone have? I am not an expert in pump applications, cavitation, vibration nor mechanical design (each of which is more important in high pressure/high power pump operation than hydrodynamic design.) — Preceding unsigned comment added by Mkoronowski (talk • contribs) 19:31, 10 July 2012 (UTC)

- You seem quite knowledgable in this subject but WP is about references for statements in the articles not *YOUR* expertise. This is sometimes regretable as references do not exist to substantiate information but it still takes a guy like you to introduce the information first. Keep up the good work and I hope you don't mind my corrections to smooth the text a bit. 99.251.125.65 (talk) 15:12, 17 August 2012 (UTC)

- figures 1, 3 and 4 are acceptable. figure 2 is confusing at best, for most common fluids and speeds, figure 5 is wrong. — Preceding unsigned comment added by Mkoronowski (talk • contribs) 19:38, 10 July 2012 (UTC)

- * HYDRODYNAMICS OF PUMPS, by Christopher Earls Brennen — Preceding unsigned comment added by Mkoronowski (talk • contribs) 19:41, 10 July 2012 (UTC)

- why has a much improved draft page not been combined with the main article? Mkoronowski (talk) 00:20, 11 July 2012 (UTC)

External Link[edit]

Here all the external links are directed to Christopher Earls Brennen's books in http://authors.library.caltech.edu website. It is not very eye soothing. Can anyone provide single webpage link, where all these books are enlisted? --Freemesm (talk) 15:19, 17 December 2012 (UTC)

centrifugul pump[edit]

Here it is the pump which we are having commomly in industry and houses.it is called centrifugal pump. most commonly it is connect with the extra motor or extra roatatindg devices.(Chain draive, belt drive). It will dischrage the liquid under 5bar presure. it is costly device.£ — Preceding unsigned comment added by 103.15.249.157 (talk) 10:33, 13 July 2013 (UTC)

Old vs new description[edit]

A while ago someone introduced a "new description", written in very bad and hard to follow English. I don't know if it adds anything of substance, but even if it does, it needs to be removed until it is rewritten in grammatically correct and comprehensible English. Unfortunately, the new version was introduced in a number of changes and several unrelated changes have been made as well, making it hard to revert to an older version without losing stuff. What should we do now? Martijn Meijering (talk) 11:49, 15 February 2015 (UTC)

- I agree something about what yo say, But you should better think about what the author say"For centuries people have trusted and used Euler equation as a basic to explain how the impeller work.

- But it was not correct. Because:

arguments prove Euler’s pump equation is not right[edit]

Take a look the method to establish the head pressure of the impeller:

1- Calculate the power consumption on the shaft by the torque that was created by the interaction force between the impeller vanes and the liquid going through it.

2- Applying energy save Neuton's law.

3- The head pressure of the output streamlines will equal the the power consumption on the shaft.

To analyse the previous method let’s look at Fig 2.1

1- The circumferential force F that impeller vanes affect on tiny mass m equal the anti-force F’ that m affect on the impeller vanes. That force created the torque on the rotary shaft.

2- The centrifugal force Fc is internal forces created by centrifugal acceleration, it appear inside m. This force have not relationship to the torque on the rotary shaft. Moreover Sir Euler never mentioned or recognized about this force,include the centrifugal acceleration that was the original can cause centrifugal force.

Follow this problem and solution it is easy to see centrifugal force Fc was outside the calculation. So that such method and such calculations are clearly serious shortcomings and serious mistake also.Nguyen thanh chinh (talk) 23:42, 7 April 2016 (UTC)

New method to establish the head pressure add by the impeller[edit]

Of course energy to create the centrifugal acceleration can not get from anywhere outside the rotary shaft. But applying conservation of momentum can not solve this problem.

In the new method, no need to mention about the energy supply by the rotary shaft but still can directly determine the energy of the output streamlines as:

1- Learning the nature of movement of mass m and found that it’s movement combination by 2 direction movement :Absolute velocity follow tangential direction and Centrifugal direction movement.

2- Not complicated to determine the value of variables : the absolute velocity of mass m and centrifugal acceleration affect on mass m

3- Quite easy to calculate the dynamic pressure and static pressure of the streamlines that going through the impeller.

I think with knowledge of classical mechanics inadequate level many people still can review and evaluation of this new approach. Because it was not quote from any source. Nguyen thanh chinh (talk) 01:12, 8 April 2016 (UTC)

27.3.127.110 (talk) 23:51, 5 April 2016 (UTC) This article is garbage !!!!! - Many of the equations in 'old' and 'new' descriptions are completely wrong - don't even have fluid density in them !!! What should be done? - Tempted to delete these sections. — Preceding unsigned comment added by 193.34.187.245 (talk) 14:04, 19 March 2015 (UTC)

- Yeah, I had another look yesterday, and tried to remove the new description stuff, but gave up because I couldn't find a workable version to revert to. Martijn Meijering (talk) 18:55, 7 April 2016 (UTC)

- Please stop making these changes. Several people have objected to them, you clearly do not have a consensus for them, as required by WP:CON. They are written in extremely bad and hard to follow English, and are completely unsuitable for an encyclopedia. If you can provide sources for your changes I'd be willing to help you clean up the English, but that needs to happen in an online draft, not in the article itself. In the meantime nearly all the material here needs to be deleted. If these are your own theories, they fall under WP:OR and should not be included at all. Martijn Meijering (talk) 08:55, 10 April 2016 (UTC)

It seems like this 'new theory' vs 'old theory' controversy has been going on for at least a few months, and yet the 'new theory' section still stands with a grand total of 0 citations/sources. As others have (sort of) pointed out, the correctness of the theory is secondary to other concerns - without citations it clearly falls under the scope of WP:OR and as such has no place on wikipedia. Basically, unless this theory is backed up by published and ideally secondary sources - so not a primary research article but at least a competent review article - it does not belong here. Whether or not it is correct, it does not belong in Wikipedia until it has been vetted in open literature. I am going to remove it, manually since it appears to be spread across multiple interleaved edits. Nguyen, please stop adding this material to the page until you can provide citations to back it up. Read up on Wikipedia policies around citation of sources and how to contribute to the community in a productive manner. Pyrilium (talk) 00:02, 30 June 2016 (UTC)

Turbine pump[edit]

This article [3] describes a turbine pump as a centrifugal pump. I think it is an Axial-flow pump. What do others think? Biscuittin (talk) 21:45, 4 December 2015 (UTC)

Multistage centrifugal pumps[edit]

The Photograph in this section is incorrect - it is not a pump for liquids, but a blower for gases (also the reference to the manufacturer on the skid is a give away).

Self-priming[edit]

The advertisement of centrifugal pumps seems to be nearly universal in claiming that they are self-priming, but none (to my admittedly limited understanding) are truly so. Would it be best to modify the segment of this article dealing with such pumps by noting that these are not truly self priming?

This arises from a recent issue that I ran into where I assumed that a cheap pump that I purchased was truly self priming. After trying to find one that actually was, it turns out that the term self priming seems to be used widely for pumps where that is not the case. The wording of this article seems to continue that practice, which is inaccurate.

A self priming pump that requires the introduction of material outside of its normal operating environment (a submerged pump is obviously self priming as it is naturally submerged in fluid), is not a self priming pump. Sfer144 (talk) 06:13, 21 February 2023 (UTC)